| • | Easy to learn and use | • | For cold and hot TIG welding |

| • | Quickly delivers reliable results | • | 4-Roll Drive for standard MIG Wires |

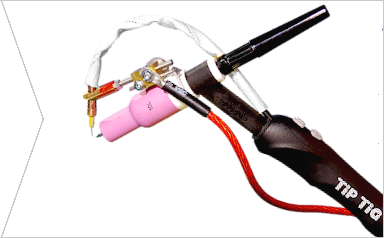

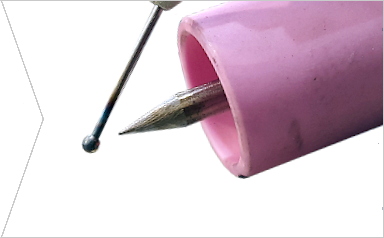

The WIG500 Comact combines the unique TiP TiG Hot Wire Feed System with a digitally controlled Inverter Power Source. Power up the WIG500 Compact and get the best out of manual TiP TiG welding. It comes with the required Torches, Cables, Hoses and Remote Control. TiP TiG International is travelling to any place for StartUp Training and assistance.

The WIG500 Compact covers the full Range of manual TiP TiG welding

| • | all Positions | • | Mild Steel | • | Aluminium |

| • | Pressure Parts | • | Duplex | • | Copper |

| • | Pressure Piping | • | Super Duplex | • | Titanium |

| • | Construction | • | Inconel | • | Hasteloy |

| • | Repairs | • | Stainless Steel | • | Zinc Plated |

The outstanding weld performance is the result of fine tuned components. High reliability is built in with the assembly of top quality components. The digital interface options make it first choice to power automated systems.

| • | Water-cooled AC/DC inverter Power Source | • | Remote Control |

| • | Integrated TiP TiG Wire Feed System | • | Automation Interface |

| • | Integrated Hot Wire Generator | • | Optional Robotic Interface |

| • | Integrated Torch Cooling System | • | Trolley mounted |

| • | Required Torches, Hoses and Cables | • | Lifting Lugs |

| Input Voltage | 350 V to 480 V |

| Input Phase | 3 |

| Input Hz | 50 / 60 Hz |

| Mains Fuses (slow-blow) | 3 x 32 A |

| Max. Connected Load | 24,6 kVA, Imax = 35,5 A, Ieff = 24 A |

| Recommended Generator Power | 34 kVA |

| Setting Range for Welding Current | 4 A - 500 A |

| Duty cycle 40 % (40 °C) | 500 A |

| Duty cycle 60 % (40 °C) | 440 A |

| Duty cycle 100 % (40 °C) | 380 A |

| Wire Feed Speed | 0,15 - 17 m / min |

| Wire Frequency | 17 Hz |

| Protection Classification | IP 23 |

| Insulation Class | F |

| System of Cooling | F |

| Net Width | 545 mm |

| Net Height | 1230 mm |

| Net Length | 1100 mm |

| Weight of WIG 500 Compact | 147 kg |

| Standards | IEC 60 974-1;-3;10 / CE / S-Safety sign / EMC class A |